You decided to take on a remodel project yourself. Everything is going great and you’re just about finished. You’ve got your drywall finished and primed, your flooring installed and it’s time for trim. So you break out your hammer and finish nails and start nailing down the first board.

Your first drive of the hammer feels great, this is going to be a breeze! Your second drive bends the nail a little bit. No problem, “I can correct this with a gentler strike at a different angle.” The finish nail now is now completely bent out of shape. You grab the claw of your hammer and yank the nail out.

Let’s try that again.

It’s a little easier this time as the nail hole has been partially carved out by the previous nail. You get a little further this time, but inevitably, the nail bends again! “It can’t be this hard. There’s so much trim in my house, the builder must have glued it all on!”

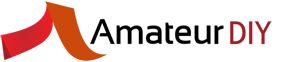

The Finish Nail Gun

Most builders and woodworkers possess a tool called a finish nail gun. Typically, it’s a pneumatic tool (connects to an air compressor) that makes easy work out of driving finish nails through wood with just the right amount of force. After learning this, you might be tempted to go out and buy the cheapest finish nailer you can find. But there are a few things to know first…

Angled vs. Straight

If you’ve already price shopped a little bit, you’ve come to find out that angled finish nailers are a bit more expensive. Don’t let that fact fool you into thinking that they’re the superior choice for every job.

Let’s look at some of the key differences:

| Angled | Straight | |

|---|---|---|

| Price | More Expensive If you plan on heavy use, or furniture building (cabinets, for example) – consider a high-quality angled nailer. |

Less Expensive If you need to install 5 pieces of trim in your living room – save your money and purchase a low-cost straight nailer. The nails for straight nail guns are typically less expensive than their angled counterpart. |

| Design | More Flexible The slanted nature of the magazine makes angled nailers ideal for shooting nails into tight spaces. |

Less Flexible The lower price comes at a cost. That cost is flexibility. The straight magazine tends to get in the way if you’re trying to drive a nail into a tight spot. |

| Application | Cabinets & Other Construction Angled nailers are typically considered a more durable way to fasten, as the nails are larger and the nail head is more pronounced. |

Trim Work The higher gauge nails (thinner) that typically go along with straight nailers are ideal for trim and other detail work that require not only that the nail head to be hidden (smaller nail head), but also a reduce chance of splitting the wood with a larger nail. |

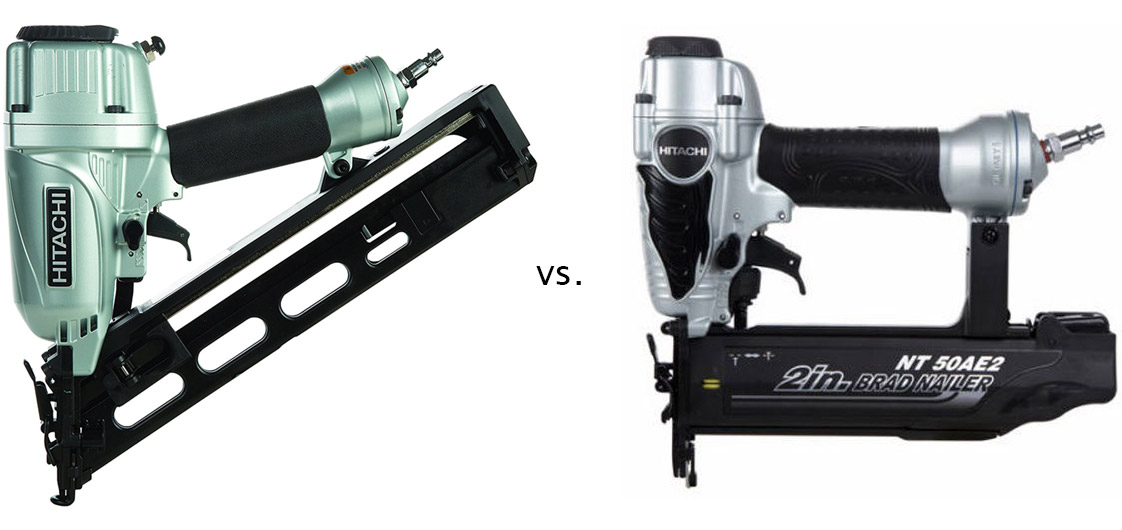

Brad vs. Finish Nailer

When we talk about brads, we’re referring to very thin nails (18-gauge or thinner) with very small heads. Brads are ideal for very light trim work, like shoe molding, where splitting can easily occur.

Brad nailers are very cost-effective, getting down to $20 for a low-end product.

Finish nails are larger (16-gauge or larger) and fasten better than brads, but they require you to fill the nail hole, if it’s visible. Whereas brads often don’t require any filling.

Electric (Cordless) vs. Pneumatic

Let’s talk about the two different ways nail guns are powered. The first, and less common, is the electric nailer.

Electric nailers are the clear choice for convenience. They don’t require another tool to power them (air compressor) and you aren’t restricted by the length of an air hose. You also won’t be slowed down waiting for an air compressor to refill.

So why would anyone purchase an air-powered pneumatic nailer? Three reasons:

-

- Smaller

- Lighter

- Cheaper

Since air tools are powered by a compressor, much of the complexity within the tool is removed.

If you already own an air compressor or plan on purchasing more than one nailer, the pneumatic option is likely the best choice for you.

Exhaust

The direction of the exhaust is a seldom thought about feature when it comes to the purchasing decision process. Exhaust refers to the air that is expelled from the gun when firing a nail. A poorly located exhaust could lead to dust being constantly blown in your face!

It seems that most nail guns have forced the air exhaust out through the back, which is great, though not perfect. A nice feature of some nail guns is the ability to adjust the direction of the exhaust away from you or your work piece.

My Choice

I’ve been using the DeWalt 51257 (pictured at the top of this post) for almost 8 years now. I’ve gone through thousands of nails, using it to build cabinets, install exterior and interior trim and many other projects.

The gun will accept a 16-gauge nail between 1″ and 2 1/2″ in length. It almost never jams and has an adjustable rear exhaust. It’s absolutely one of my top 5 favorite tools.

I bought it at home depot 8 years ago for over $200, but it looks like Amazon now has it in the $150 range.